Sinoright Blog

Tensile Strength Strong High Temperature Corrosion Resistanc

Production through injection molding can simplify and standardize parts for engineers, and combine multiple parts into a functional component with fewer parts and more convenient installation, thereby accelerating assembly speed and reducing system costs.

Under the condition of 260 ℃ (500 ℉), aging without heating under stress for more than 5000 hours, without loss of tensile strength performance; Stable in size and with excellent creep resistance, fatigue resistance, and moisture resistance; The tolerance to aviation fuel, hydraulic oil, deicing solution, insecticide, cleaning fluid, fire extinguishing chemicals, water, salt, and steam; The fire rating is UL94 V-0, with characteristics such as low smoke and low toxic gas emissions.

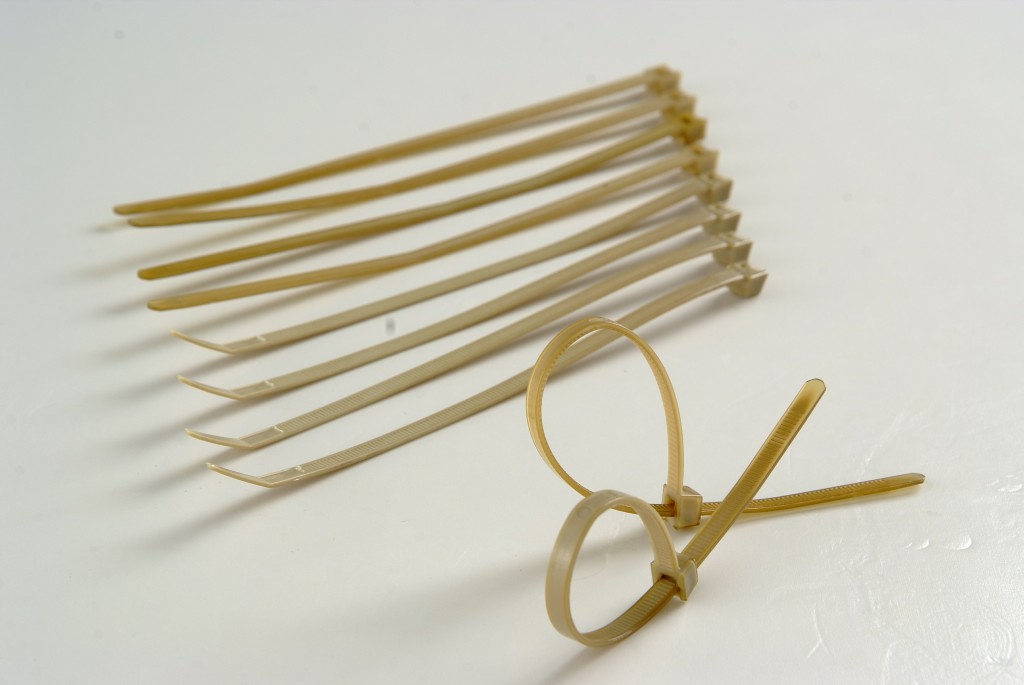

We have developed a new type of zip tie using PEEK polyether ether ketone material that has the ability to withstand high corrosive environments, for tying and fixing functions in high-temperature application environments.

In the fields of petroleum drilling applications, as well as aerospace applications such as satellites and sensitive military systems, PEEK cable ties can provide fast, safe, and stable wire and cable management solutions. Wires and cables extend from one end of the aircraft fuselage to the other, or wrap around electric pump engines. These wires and cables must be tied and secured to avoid contact with heat sources or sharp edges.

For most applications, cable ties made of nylon are sufficient, but in high-temperature applications such as oil drilling equipment, cable ties are used to fix small bundles of wires to the pumping pipeline. Nylon cable ties often melt, which hinders the operation of the pumping equipment.

Therefore, utilizing the heat resistance characteristics of PEEK material, we provide customers with cable ties that can maintain stability. In the case of deep drilling, the temperature may reach 200 ° C (392 ° F).

The petroleum industry has chosen PEEK material because it is the only material that can still perform well in such harsh environments.

PEEK can withstand temperatures up to 260 ° C (500 ° F) and has excellent resistance to current, radiation, and chemical erosion environments.

Under high temperature conditions, PEEK also exhibits excellent chemical corrosion resistance in saltwater and crude oil. Even after prolonged exposure to high-pressure and high-temperature water, it still maintains long-term reliability.

PEEK has low moisture absorption and low gas release performance, making it particularly suitable for aerospace applications. Low moisture absorption ensures the dimensional stability of the tie, and PEEK is halogen-free, emitting only minimal smoke and toxic gases during combustion, making it durable.

PEEK has excellent mechanical properties, and its mechanical strength meets the requirements, allowing us to mold components with much higher strength than nylon components. This type of cable tie has a single piece, injection molded structure, which can provide maximum strength and has adjustability for fixing wire harnesses of different sizes.

Wear is a major issue with electrical cables, especially on airplanes. If the cables are encapsulated in plastic coatings, the sharp edges of nylon ties can easily cause the coating to wear. The use of molded PEEK cable ties will not cause this phenomenon. PEEK material has inherent lubrication properties and high wear resistance.

PEEK zip tie size parameters:

Total length: 155mm; 187.5mm

Bandwidth: 2.7mm; 3.7mm

Ring tensile strength (minimum value): 230N (23.5kgf)

Tie form: straight through

Temperature resistance: -60 ℃~+240 ℃