Sinoright Blog

Ultra-thin PEEK Film used for Speaker or Head Phone Vibratio

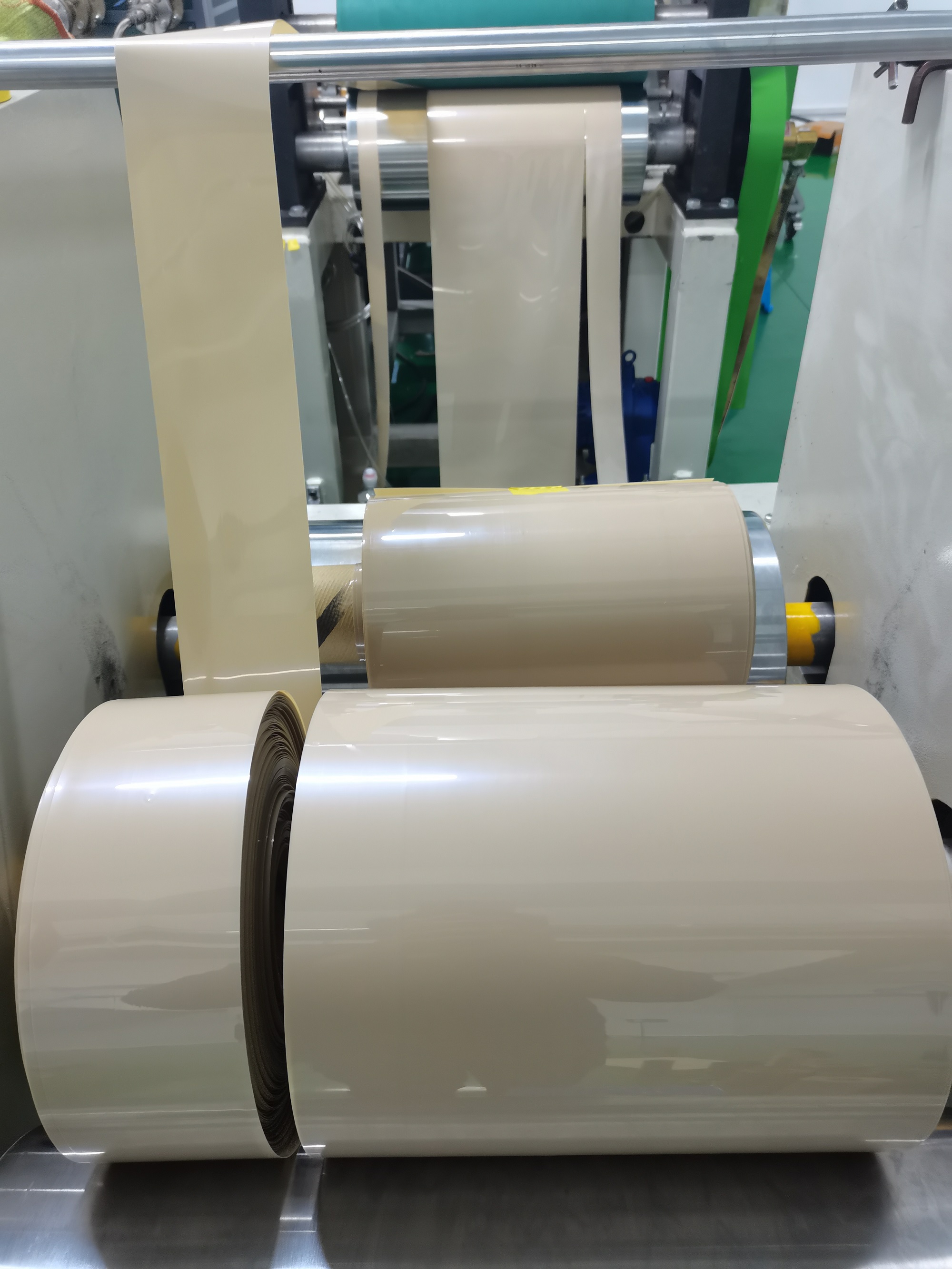

0.3MM PEEK FILM

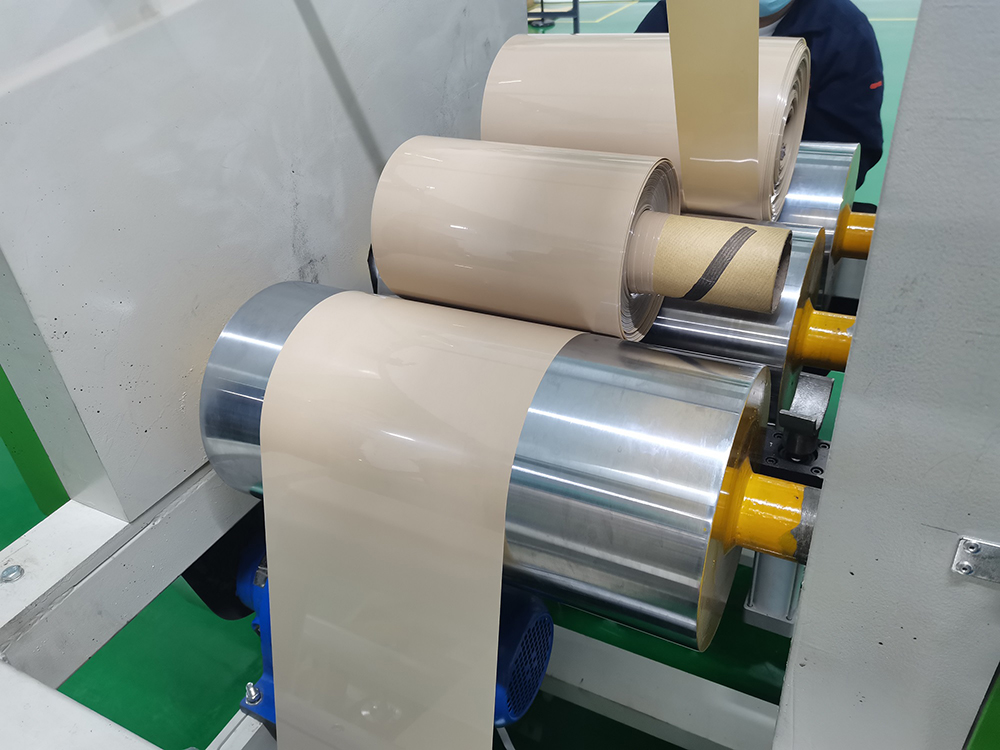

0.05MM PEEK FILM

0.05MM AMORPHOUS PEEK FILM

I. Mechanical properties: A plastic film that balances toughness and rigidity, especially its excellent fatigue resistance to alternating stress, which is outstanding among all plastics and comparable to alloy materials.

II. High temperature resistance: It can withstand the temperature of lead-free welding process, with a film thickness between 30-155 microns. The RTI level for impact free mechanical applications is 220 ℃, while for electrical applications it is 200 ℃. The carbonization point remains stable until 500 ℃.

III. Self lubrication: It has outstanding sliding characteristics among all plastic films and is suitable for use with strict requirements for low friction coefficient and wear resistance. Especially, PEEK films modified by mixing carbon fiber and graphite in a certain proportion have better self-lubricating performance.

IV. Chemical resistance (corrosion resistance): It has excellent chemical resistance. Among ordinary chemicals, only concentrated sulfuric acid can dissolve or destroy it, and its corrosion resistance is similar to nickel steel.

V. Flame retardancy: A highly stable polymer that can achieve the highest flame retardant standard without adding any flame retardants. It is halogen-free and complies with the IEC 61249-2-21 standard.

VI. Peel resistance: It has excellent peel resistance and can be made into electromagnetic wires with thin coatings, which can be used under harsh conditions.

VII. Fatigue resistance: It has better fatigue resistance among all resin films.

VIII. Radiation resistance: The ability to withstand high radiation is very strong, and it can still maintain good insulation ability under ultra-high radiation doses.

IX. Hydrolysis resistance: Not affected by the chemical effects of water and high-pressure water vapor, products made of this thin film material can still maintain excellent properties when continuously used in high-temperature and high-pressure water.

X. Melting processability: When the temperature above the melting point is reached, it can fuse with the metal, and ultrasonic sealing is easy. PET film can also be sealed, and laser can dissolve and print.

XI. High sound clarity: Avoid auditory fatigue caused by metal film noise and achieve better acoustic performance.

XII. Environmental Protection and Safety: Lightweight, recyclable, compliant with RoHS standards, can be used to manufacture products that meet the same directive requirements, and meets the requirements of the US Food and Drug Administration (FDA).

PEEK films are widely used in aerospace, automotive manufacturing, industrial fields, medical devices, insulation materials and other fields: pressure-sensitive tapes, pressure sensor films, printed circuit substrates, acoustic speaker films, high-temperature labels, capacitors, gaskets in high-speed motors, composite gaskets in mobile phone hinges, laser printed labels, metal foil direct thermal bonding, flexible surface heaters, semiconductor process protective films and other related industries. Meanwhile, thermoplastic films can achieve ideal versatility and flexibility through secondary processing, including adhesion, surface treatment, coating, slitting, stamping, hot lamination, hot welding and sealing, hot forming, printing and metalization.

Wide range of size selection:

Thin films with thickness ranging from 0.03mm to 0.5mm and width ranging from 350mm to 400mm can be produced. Large quantities can be cut and rolled according to customer requirements, with a thickness accuracy of ± 0.01mm.